1. The steel-welded frame could make sure high strength, high rigidity and high accuracy.

2. Using of mechanical forced synchro system, both sides of sliders move in parallel by synchro axis.

3. Deflection compensation unit is installed in the upper mold,Upper mold clamping device is an option.

4. When NC press brake, X-axis backgauge is driven by servo motor ,adoapted ball-screw and linear guide way.

5. When NC press brake, ram stroke are controled by servo moto,it could make sure higher positioning accuracy.

Quick Detail:

| Name | Other Names | Brand Name | CMC |

| Light pole machines |

light pole making equipments Light pole producing line Lamp post making machines

|

Feature | We can supply the whole production line.And we also can specially design for customer |

| Light pole range |

Pole diameter:60-500mm Pole length:16000mm |

Usage Industrial | Street light pole industrial |

1. Light Pole Taper Steel Plate Cutting Process

We use cut to length machine to uncoil, level, cut, scrape edge and taper, then we can get one side small width, one side big width steel plate.![]()

![]()

![]()

2. Light Pole Taper Steel Plate Bending Process

We use CNC tandem press brake machine to bend conical or polygon shape pole by special tooling.

![]()

![]()

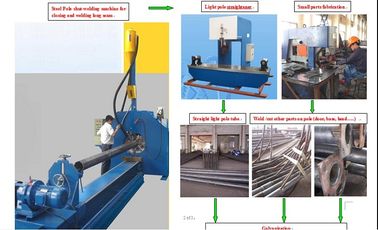

3. Light Pole Shut Welding Machine Process:

After bended by press brake machine, the pole has been formed, but there will a seam.Therefore we use our special design shut welding machine to weld this seam automatically.

![]()

![]()

![]()

4. Light Pole Straighten Process:

After welding, the pole will be bent, not straight, then we need use straightening machine to straight.

![]()

5. Base Plate Making Process

We use shearing machine to cut square shape , then ironwoker to punch holes.

![]()

![]()

![]()

6. Base Plate Automatcial Welding Process

we use this equipment to weld base plate with light pole

![]()

![]()

7. Light pole door cutting machine

We specially designed this light pole door cutting machine to cut door for conical, octagonal light pole.The cutting shape can be circle, square, rectrangle...

![]()

9. Light pole top part drilling hole process

It is suitable for light pole top fixing hole quick drilling process.Once finish two holes.

![]()

![]()

8. Light pole top part bending process

We design special fixture to clamp light pole top part, then use winch to pull and bend

![]()

Quick Detail:

| Name | Other Name | Brand Name | CMC |

| Single Rate Round/circle/conical light pole tooling for press brake machine to bend circle pole |

|

Feature | In one set of tooling, it can have one taper rate: 11/1100, full length 16 meters. in whole word, the 95% pole is 11/11000 rate |

| Capacity | To make min OD 60mm | Advantages | With this conical tooling, the light pole is very round |

Application:

Making conical light pole on CNC press brake

Specifications

| Conical light pole tool | ||||||||||||||||

| For bottom tool,one side with taper rate 11/1000 | ||||||||||||||||

| tool length | 16 | m | ||||||||||||||

| taper rate: | 11 | /1000 | ||||||||||||||

| small end OD: | 60 | mm | ||||||||||||||

| Big end OD: | 236 | mm | ||||||||||||||

| bascial thickness: | 4 | mm | ||||||||||||||

| It can do the following size CONICAL CIRCULAR light pole. | ||||||||||||||||

| Light pole length,small end outer diameter,big end outer diameter table | ||||||||||||||||

| small end OD (mm) | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 |

| pole length (m) | Big end outer diameter table (mm) | |||||||||||||||

| 2 | 82 | 92 | 102 | 112 | 122 | 132 | 142 | 152 | 162 | 172 | 182 | 192 | 202 | 212 | 222 | 232 |

| 3 | 93 | 103 | 113 | 123 | 133 | 143 | 153 | 163 | 173 | 183 | 193 | 203 | 213 | 223 | 233 | |

| 4 | 104 | 114 | 124 | 134 | 144 | 154 | 164 | 174 | 184 | 194 | 204 | 214 | 224 | 234 | ||

| 5 | 115 | 125 | 135 | 145 | 155 | 165 | 175 | 185 | 195 | 205 | 215 | 225 | 235 | |||

| 6 | 126 | 136 | 146 | 156 | 166 | 176 | 186 | 196 | 206 | 216 | 226 | 236 | ||||

| 7 | 137 | 147 | 157 | 167 | 177 | 187 | 197 | 207 | 217 | 227 | ||||||

| 8 | 148 | 158 | 168 | 178 | 188 | 198 | 208 | 218 | 228 | |||||||

| 9 | 159 | 169 | 179 | 189 | 199 | 209 | 219 | 229 | ||||||||

| 10 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | |||||||||

| 11 | 181 | 191 | 201 | 211 | 221 | 231 | ||||||||||

| 12 | 192 | 202 | 212 | 222 | 232 | |||||||||||

![]()

Detailed Product Description:

| CNC Control System: |

Delem DA-52 |

Function: | Bending Steel Plates |

| Product Name: | Press Brake Machine | Steel Sheet Thickness: | 6mm |

| Steel Sheet Width: | 3200mm | Use: | Metal Plates |

Quick Detail:

6mm V Groove CNC Hydraulic Press Brake Machine for For Bending Steel Plates WE67K-160T/3200mm

Select And Use DELEM DA52 CNC Control System

1. punch force: 1600KN

2. bending max steel sheet width :3200mm

3. bending max steel sheet thickness : 6mm

Description:

1. With stylish design, high rigidity, high speed.

2. Electro-hydraulic servo system,closed loop control system controls accuracy.

3. Worktable adopts hydraulic deflection compensation to ensure the accuracy of the workpiece.

4. Back gauge is driven by servo motor ,adoapted ball-screw ,and linear guide way,it could make sure positioning accuracy.

Applications:

CNC Hydraulic Press Brake is widely used in large steel structure, steel tower, truck carriage, electric cabinet, decoration industrial. With different dies provided, the subscriber can get the metal plate bent into different shapes of work pieces.

Specifications:

Main Technical Features

| NO. | Name | Value | Unit | Remark | |

| 1 | Working force | 1600 | KN | ||

| 2 | Length of table | 3200 | mm | ||

| 3 | Distance of column | 2650 | mm | ||

| 4 | Throat depth | 320 | mm | ||

| 5 | Open height | 500 | mm | ||

| 6 | stroke | 200 | mm | ||

| 7 | Speed of ram slide block | Approach | 100 | mm/s | |

| Working | 10 | mm/s | |||

| Return | 90 | mm/s | |||

| 8 | Main motor | 11 | KW | ||

| 9 | Overall dimension | Length | 3200 | mm | |

| Width | 2050 | mm | |||

| Height | 2915 | mm | |||

| 10 | Weight | 11000 | Kg | ||

| 11 | Volume of oil tank | 400 | L | ||

Competitive Advantage:

1) Our machine performance quality and chcheap, known in the industry.

2) One year guarantee.

3) Fast and high quality after-sales service.

4) We can design the machines according to customers’ special requirement.

5) We have professional team for service.

Communication with customers

A: what is difference during DA-52, DA-56, DA-65W and DA66T?

About CNC press brake machines, usually, we suggest four kinds of controller system more often: Delem DA-52, DA-56, DA-65W, DA66T Following is their characters:

DA-52 control system:

DA-56 control system:

DA65W controller system:

DA66T controller system:

MANUFACTURER: WUXI JINQIU MACHINERY CO.,LTD

Detailed Product Description:

| CNC Control System: |

Delem DA-41 Estun E10 E200 Jin Qiu DTC800 |

Function: | Bending Steel Plates |

| Product Name: | Press Brake Machine | Steel Sheet Thickness: | 8m |

| Steel Sheet Width: | 4000mm | Use: | Metal Plates |

Quick Detail:

High quality bending Press Brake Machine 250T/4000mm

1. punch force: 250KN

2. bending max steel sheet width :4000mm

3. bending max steel sheet thickness :8m

Description:

1. The steel-welded frame could make sure high strength, high rigidity and high accuracy.

2. Using of mechanical forced synchro system, both sides of sliders move in parallel by synchro axis.

3. Deflection compensation unit is installed in the upper mold,Upper mold clamping device is an option.

4. When NC press brake, X-axis backgauge is driven by servo motor ,adoapted ball-screw and linear guide way.

5. When NC press brake, ram stroke are controled by servo moto,it could make sure higher positioning accuracy.

Applications:

Press Brake Machine is widely used in large steel structure, steel tower, truck carriage, electric cabinet, decoration industrial. With different dies provided, the subscriber can get the metal plate bent into different shapes of work pieces.

Specifications:

Main Technical Features

| NO. | Name | Value | Unit | Remark | |

| 1 | Working force | 250 | KN | ||

| 2 | Length of table | 4000 | mm | ||

| 3 | Distance of column | 3100 | mm | ||

| 4 | Throat depth | 400 | mm | ||

| 5 | Open height | 480 | mm | ||

| 6 | stroke | 250 | mm | ||

| 7 | Speed of ram slide block | Approach | 70 | mm/s | |

| Working | 8 | mm/s | |||

| Return | 80 | mm/s | |||

| 8 | Main motor | 18.5 | KW | ||

| 9 | Overall dimension | Length | 4100 | mm | |

| Width | 2500 | mm | |||

| Height | 2960 | mm | |||

| 10 | Weight | 18000 | Kg | ||

| 11 | Volume of oil tank | 640 | L | ||

Competitive Advantage:

1) Our machine performance quality and chcheap, known in the industry.

2) One year guarantee.

3) Fast and high quality after-sales service.

4) We can design the machines according to customers’ special requirement.

5) We have professional team for service.

MANUFACTURER: WUXI JINQIU MACHINERY CO.,LTD

Detailed Product Description:

| CNC Control System: |

Delem DA-41 Estun E10 E200 Jin Qiu DTC800

|

Function: | Bending Steel Plates |

| Product Name: | Press Brake Machine | Steel Sheet Thickness: | 3mm |

| Steel Sheet Width: | 2500mm | Use: | Metal Plates |

Quick Detail:

Hydraulic Steel Plate Press Brake Machine 63T/2500mm

1. punch force: 630KN

2. bending max steel sheet width :2500mm

3. bending max steel sheet thickness :3mm

Description:

1. The steel-welded frame could make sure high strength, high rigidity and high accuracy.

2. Using of mechanical forced synchro system, both sides of sliders move in parallel by synchro axis.

3. Deflection compensation unit is installed in the upper mold,Upper mold clamping device is an option.

4. When NC press brake, X-axis backgauge is driven by servo motor ,adoapted ball-screw and linear guide way.

5. When NC press brake, ram stroke are controled by servo moto,it could make sure higher positioning accuracy.

Applications:

Press Brake Machine is widely used in large steel structure, steel tower, truck carriage, electric cabinet, decoration industrial. With different dies provided, the subscriber can get the metal plate bent into different shapes of work pieces.

Specifications:

Main Technical Features

| NO. | Name | Value | Unit | Remark | |

| 1 | Working force | 630 | KN | ||

| 2 | Length of table | 2500 | mm | ||

| 3 | Distance of column | 2050 | mm | ||

| 4 | Throat depth | 250 | mm | ||

| 5 | Open height | 340 | mm | ||

| 6 | stroke | 100 | mm | ||

| 7 | Speed of ram slide block | Approach | 70 | mm/s | |

| Working | 10 | mm/s | |||

| Return | 60 | mm/s | |||

| 8 | Main motor | 5.5 | KW | ||

| 9 | Overall dimension | Length | 2750 | mm | |

| Width | 1725 | mm | |||

| Height | 2215 | mm | |||

| 10 | Weight | 4500 | Kg | ||

| 11 | Volume of oil tank | 240 | L | ||

Competitive Advantage:

1) Our machine performance quality and chcheap, known in the industry.

2) One year guarantee.

3) Fast and high quality after-sales service.

4) We can design the machines according to customers’ special requirement.

5) We have professional team for service.

MANUFACTURER: WUXI JINQIU MACHINERY CO.,LTD

Detailed Product Description:

| CNC Control System: |

Delem DA-41

|

Function: | Bending Steel Plates |

| Product Name: | Press Brake Machine | Steel Sheet Thickness: | 4mm |

| Steel Sheet Width: | 4000mm | Use: | Metal Plates |

Quick Detail:

DA41 Hydraulic Steel Plate Press Brake Machine for Stainless steel decoration industry 125T/4000mm

1. punch force: 1250KN

2. bending max steel sheet width :4000mm

3. bending max steel sheet thickness :4mm

Description:

1. The steel-welded frame could make sure high strength, high rigidity and high accuracy.

2. Using of mechanical forced synchro system, both sides of sliders move in parallel by synchro axis.

3. Deflection compensation unit is installed in the upper mold,Upper mold clamping device is an option.

4. When NC press brake, X-axis backgauge is driven by servo motor ,adoapted ball-screw and linear guide way.

5. When NC press brake, ram stroke are controled by servo moto,it could make sure higher positioning accuracy.

Applications:

Press Brake Machine is widely used in large steel structure, steel tower, truck carriage, electric cabinet, decoration industrial. With different dies provided, the subscriber can get the metal plate bent into different shapes of work pieces.

Specifications:

Main Technical Features

| NO. | Name | Value | Unit | Remark | |

| 1 | Working force | 1250 | KN | ||

| 2 | Length of table | 4000 | mm | ||

| 3 | Distance of column | 3100 | mm | ||

| 4 | Throat depth | 250 | mm | ||

| 5 | Open height | 365 | mm | ||

| 6 | stroke | 100 | mm | ||

| 7 | Speed of ram slide block | Approach | 60 | mm/s | |

| Working | 8 | mm/s | |||

| Return | 40 | mm/s | |||

| 8 | Main motor | 7.5 | KW | ||

| 9 | Overall dimension | Length | 4300 | mm | |

| Width | 1990 | mm | |||

| Height | 2575 | mm | |||

| 10 | Weight | 9000 | Kg | ||

| 11 | Volume of oil tank | 280 | L | ||

Competitive Advantage:

1) Our machine performance quality and chcheap, known in the industry.

2) One year guarantee.

3) Fast and high quality after-sales service.

4) We can design the machines according to customers’ special requirement.

5) We have professional team for service.

MANUFACTURER: WUXI JINQIU MACHINERY CO.,LTD

Detailed Product Description:

| CNC Control System: |

Delem DA-41 Estun E10 E200 Jin Qiu DTC800

|

Function: | Bending Steel Plates |

| Product Name: | Press Brake Machine | Steel Sheet Thickness: | 12mm |

| Steel Sheet Width: | 4000mm | Use: | Metal Plates |

Quick Detail:

Bending Steel Plates Press Brake Machine For steel tower 400T/4000mm

1. punch force: 4000KN

2. bending max steel sheet width :4000mm

3. bending max steel sheet thickness :12mm

Description:

1. The steel-welded frame could make sure high strength, high rigidity and high accuracy.

2. Using of mechanical forced synchro system, both sides of sliders move in parallel by synchro axis.

3. Deflection compensation unit is installed in the upper mold,Upper mold clamping device is an option.

4. When NC press brake, X-axis backgauge is driven by servo motor ,adoapted ball-screw and linear guide way.

5. When NC press brake, ram stroke are controled by servo moto,it could make sure higher positioning accuracy.

Applications:

Press Brake Machine is widely used in large steel structure, steel tower, truck carriage, electric cabinet, decoration industrial. With different dies provided, the subscriber can get the metal plate bent into different shapes of work pieces.

Specifications:

Main Technical Features

| NO. | Name | Value | Unit | Remark | |

| 1 | Working force | 4000 | KN | ||

| 2 | Length of table | 4000 | mm | ||

| 3 | Distance of column | 3100 | mm | ||

| 4 | Throat depth | 400 | mm | ||

| 5 | Open height | 560 | mm | ||

| 6 | stroke | 320 | mm | ||

| 7 | Speed of ram slide block | Approach | 70 | mm/s | |

| Working | 7.5 | mm/s | |||

| Return | 60 | mm/s | |||

| 8 | Main motor | 30 | KW | ||

| 9 | Overall dimension | Length | 4080 | mm | |

| Width | 2410 | mm | |||

| Height | 3360 | mm | |||

| 10 | Weight | 22300 | Kg | ||

| 11 | Volume of oil tank | 700 | L | ||

Competitive Advantage:

1) Our machine performance quality and chcheap, known in the industry.

2) One year guarantee.

3) Fast and high quality after-sales service.

4) We can design the machines according to customers’ special requirement.

5) We have professional team for service.

MANUFACTURER: WUXI JINQIU MACHINERY CO.,LTD